High-voltage wound motor slip ring is a high-speed sliding contact part for transmitting high voltage and high current to the water resistance cabinet, which consists of three-phase rotor collector ring, carbon brushes and carbon brush holder. The high-speed friction between the slip ring and the carbon brush produces more waste carbon powder when the slip ring rotates, and the carbon powder adheres to the slip ring and the carbon brush, causing the insulation of the motor to drop, it brings serious hidden trouble to the safe operation of motor.

To solve this problem, our company has designed a manual/automatic blowing control device for high-voltage wound motor when starting and stopping, which has achieved relatively satisfactory results.

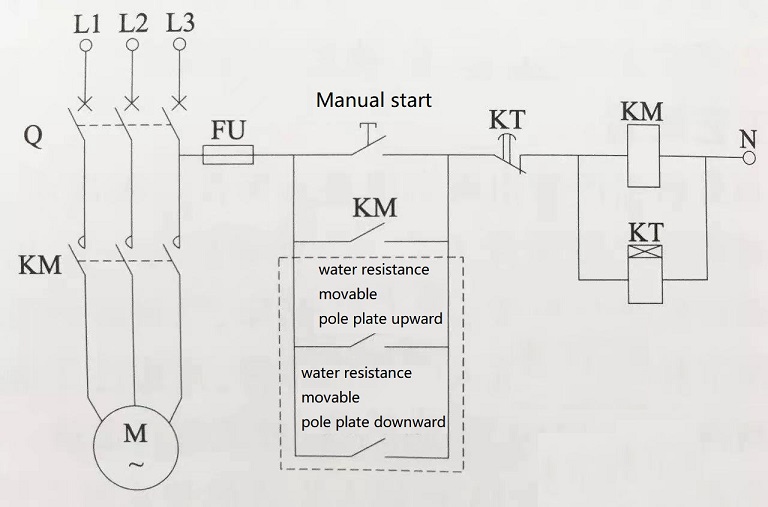

According to the power of each high-voltage motor and the wear of carbon powder, we installed 300 ~ 500W centrifugal fan at the position of 100mm from the slip ring and the carbon brush, because the outlet of the fan is only about 80mm × 80mm, therefore, the air outlet is made into a inclined horn mouth to blow evenly on the three-phase sliding ring and the carbon brush. The fan is controlled by manual or automatic methods, and its electrical control principle is shown in picture.

The up and down contacts of the water resistance movable plate are taken from the positive and negative running contactor of the water resistance cabinet movable plate, and the chain centrifugal fan automatically sweeps the slip ring and the carbon brush and its surroundings, time Relay KT controls purge time, set to 1 min.