Enclosure Type

The enclosure type shows how well the motor is protected from the environment.

This is the area where IEC standards get very specific. “Open drip-proof” and “totally enclosed” are the descriptive words NEMA uses.

The most common enclosures are:

Open Drip Proof (ODP) Allows air to circulate through the windings for cooling but prevents drops of liquid from falling into the motor within a 15 degree angle from vertical. Typically used for indoor applications in relatively clean and dry locations.

Open Drip Proof (ODP) Allows air to circulate through the windings for cooling but prevents drops of liquid from falling into the motor within a 15 degree angle from vertical. Typically used for indoor applications in relatively clean and dry locations.

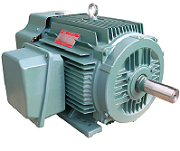

Totally Enclosed Fan Cooled (TEFC) No airflow through the motor. It has a fan blowing air over the outside of the enclosure. This motor is not water or air tight. Outside air and moisture can enter the motor, but not enough to interference with normal operation. Used for outdoor and dirty locations.

Totally Enclosed Fan Cooled (TEFC) No airflow through the motor. It has a fan blowing air over the outside of the enclosure. This motor is not water or air tight. Outside air and moisture can enter the motor, but not enough to interference with normal operation. Used for outdoor and dirty locations.

Totally Enclosed Non-Ventilated (TENV) Similar to TEFC but without cooling fan. No vent opening, tightly enclosed to prevent the free exchange of air, but not airtight. Suitable for uses which are exposed to dirt or dampness, but not very moist or hazardous locations.

Totally Enclosed Non-Ventilated (TENV) Similar to TEFC but without cooling fan. No vent opening, tightly enclosed to prevent the free exchange of air, but not airtight. Suitable for uses which are exposed to dirt or dampness, but not very moist or hazardous locations.

Totally Enclosed Air Over (TEAO) Dust-tight fan and blower duty motors designed for shaft mounted fans or belt driven fans. The motor must be mounted within the airflow of the fan.

Totally Enclosed Air Over (TEAO) Dust-tight fan and blower duty motors designed for shaft mounted fans or belt driven fans. The motor must be mounted within the airflow of the fan.

Totally Enclosed Wash Down (TEWD) Designed to withstand high pressure wash-downs or other high humidity or wet environments. Available on TEAO, TEFC and TENV enclosures.

Totally Enclosed Hostile and Severe Environment motors are used in extremely moist or chemical environments, but not for hazardous areas.

Explosion Proof Enclosures (EXPL) The motors are designed to withstand an internal explosion of specified gases or vapors and not allow the internal flame or explosion to escape. Available on TEFC or TENV eclousure.

Hazardous Locations (HAZ) For use in various hazardous locations. For Class I, II, II hazardous locations.

However, IEC uses numbers to describe enclosures, and there are a lot of them.

The first digit indicates how well-protected the motor is against entry of solid objects such as dust, wire, tools, or fingers.

Here’s what the first digit means:

0 - No protection.

1 - Protection against objects larger than 50 mm (about 2 in.) in diameter, like hands.

2 - Protection against objects larger than 12 mm (about 1/2 in.) in diameter, like fingers.

4 - Protection against objects larger than 1 mm (about 0.04 in.) in diameter, like small tools and wires.

5 - Complete protection, including dust-tightness.

6 - IP 66 does not apply to motors

The second digit signifies protection against water entry.

These ratings are:

0 - No protection.

I - Protected from water falling straight down.

2 - Protected from water falling as much as 15 degrees from vertical.

3 - Protected from spraying water as much as 60

degrees from the vertical.

4 - Protected from splashing water coming from any

direction.

5 - Protected from water sprayed from a nozzle in any

direction.

6 - Protected from heavy seas.

7 - Protected against immersion for a given time.

8 - Protected against immersion indefinitely.

For most industrial applications, IP 22 relates to open drip-proof motors, IP 44 or IP 54 to totally enclosed (like NEMA 12), IP 45 to weatherproof, and IP 55 to washdown -duty motors.

References

International Electrotechnical Commission (IEC) www.iec.ch

National Electrical Manufacturers Association (NEMA) www.nema.org