1. High voltage motor terminal box or junction box

The junction box consists of main parts such as the box base, the cover and the insulating sleeve. The junction box with rated voltage of 3KV and above, the insulating sleeve is resinized pressing piece or electric porcelain piece, and the low-voltage outlet box adopts stud structure.

The entire junction box of the high-voltage motor should be sealed and sealed from the main body of the motor to prevent water and dust from entering the inside of the box and the motor. The junction box is protected to IP54 and should be designed as IP55 if necessary. There are grounding devices and wiring signs in the junction box (some motor manufacturers identify wiring instructions on the nameplate), and if necessary, can be equipped with lightning arresters or current transformers.

2. Air to air cooler

The air-to-air cooler means that the cooling pipe in the cooler absorbs the heat in the circulating air in the motor, and is carried away by the cold air blown into the cooling pipe by the external fan mounted on the non-shaft extending end. It is used on fully enclosed motors. The two ends of the cooling tube are squeezed and expanded, and then fixed on both end plates, which has good sealing performance.

The entire cooler is immersed in anti-rust treatment. The cooler is placed on top of the frame and can be removed for installation and lifting. During the installation and use, it is necessary to pay attention to the steering compliance of the cooler motor to avoid unnecessary trouble.

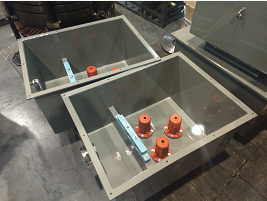

3.Water-air cooler

The so-called water-air cooler is that the cooling pipe in the cooler absorbs the heat in the circulating air in the motor and is taken away by the cooling water that is sent into the cooling tube. It is used on the fully enclosed motor and has better cooling effect and noise reduction effect than the air-air cooler. The cooling pipe is made of a special tube with a heat sink, and the two ends are squeezed and expanded, and then fixed on both end plates. Has a good sealing performance. The cooler is subjected to a hydrostatic test at a pressure of 0.5 MPa and can be withdrawn from its outer casing for easy access and replacement.

The water-air cooler is placed on the top of the base and can be disassembled for installation and lifting. The cooling water needs to meet the industrial tap water standard. The inlet water temperature should not be higher than 33 °C, and should not be lower than 5 °C. The amount of influent water can be seen in the outline drawing provided randomly, and the inlet water pressure is 0.1-0.2Mpa.

4.Protection cover

The protective class of IP23 and IPW23 has several bends in the air inlet, which meets the requirements of waterproof and solid-proof to a certain extent. The protective cover of IP24 has more than three bends in the air inlet and dust cleaning outlet. According to the need, the motor used in the open air can also be equipped with a protective cover outside the motor, which can play a certain role in blocking the sun and rain.

5. Temperature measuring element and heater

According to user's requirement, temperature measuring elements can be embedded in stator windings and bearings, and heaters can be installed in motors. When the motor shuts down or the winding insulation resistance is low, the heater is heated electrically to prevent condensation or increase the winding insulation resistance.

Shanghai Douli Power high voltage motors use winding temperature measurement,bearing temperature element and heater as our standard for high voltage motor. www.doulipower.com

6.Impact protection device

The impact protection device is set according to the user's technical requirements, including lightning arresters, current transformers, overvoltage protection devices, and the like. These devices can be mounted on the motor or placed separately and can be easily plugged into the circuit to protect the motor from line shocks caused by switching operation faults or lightning. These live devices are closed to ensure operator safety.